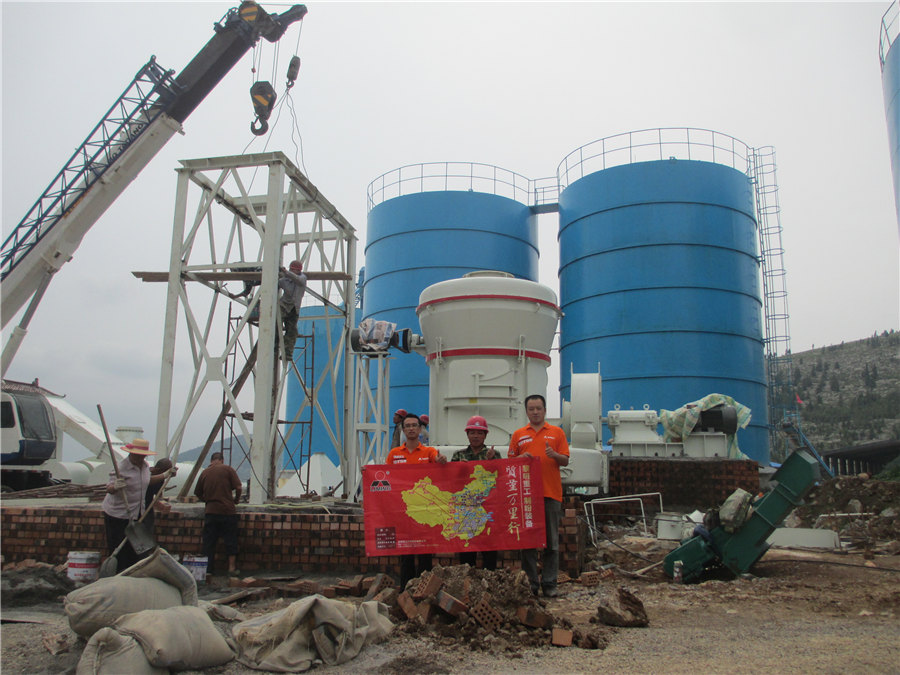

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

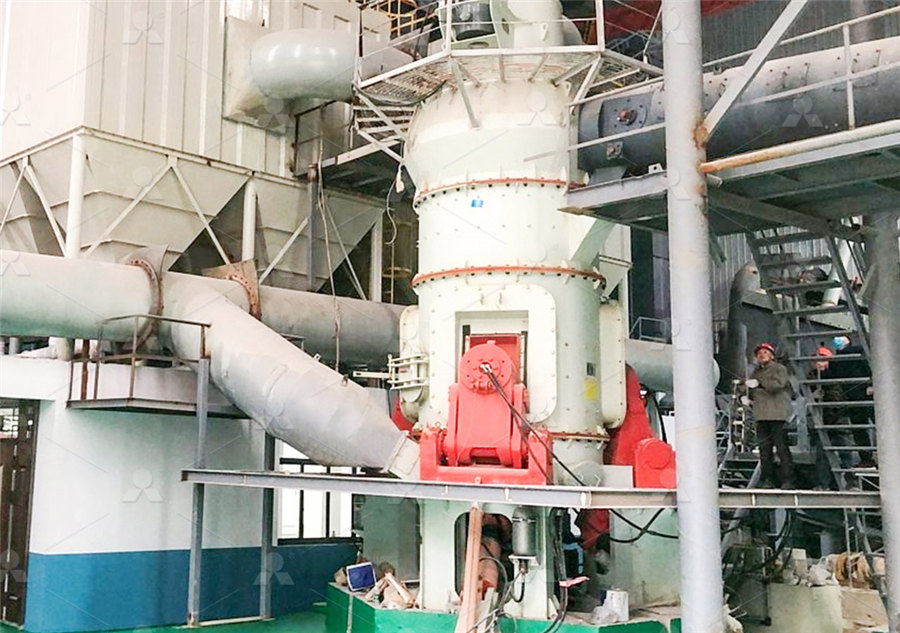

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

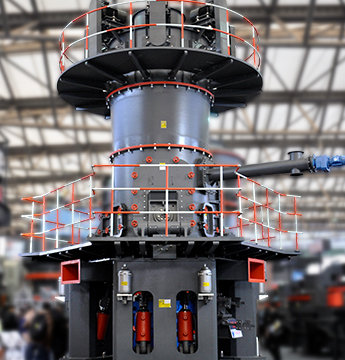

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Wet Ball Grinding Mill With High Efficiency Exports To Russia

sbm wet ball mill machine distributor in russiamd

4 天之前 — sbm wet ball mill machine distributor in russiaAggregate,Mineral and Agricultural Equipment SolutionsMcLanahan can help you solve a variety of problems across The wet grinding and dispersing process defines your end product characteristics Our solutions include cuttingedge bead mills and threeroll mills, supported by unrivaled process and application expertise, to give Wet Grinding and Dispersing Equipment Bühler 5 天之前 — The highspeed mill system Zeta® with improved peg grinding system optimizes your production capacity, energy demand and quality Designed for circulation operation and multipass operation, you achieve Circulation Mill System ZETA® Grinding2017年8月29日 — The requirements for the production of highquality balls with hardness up to HRC 65 are outlined, in terms of the chemical composition of the steel, the equipment Improving the Quality of Steel Grinding Balls Springer

.jpg)

Mechanistic modeling and simulation of a wet planetary ball mill

2023年11月1日 — Abstract The planetary mill is one of the most commonly used mills for ultrafine grinding in the laboratory, given its ability to reach higher intensity of the 2023年11月28日 — In response to the Natural Resources Canada “Crush It Challenge,” Corem partnered with the University of British Columbia and led a project to develop and Replacement of Wet Ball Milling with HighPressure Grinding China Wet Grinding Machine wholesale Select 2024 high quality Wet Grinding Machine products in best price from certified Chinese Grinding Mill manufacturers, Polishing Wet Grinding Machine MadeinChina2017年7月26日 — In this research, nanoscale high energy wet (NHEW) ball milling is first investigated for the synthesis of NG catalysts to make conventional problems such as Nitrogen‐doped graphene catalysts: High energy wet ball

Analysis of the main trends in the development of the production

It is shown that grinding balls of domestic production have lower performance characteristics in relation to foreign counterparts, which is due to the technological features of their 2024年1月13日 — Table 1 Chemical composition of typical grinding media (% wt) Adapted from [24] 211 Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in Grinding Media in Ball MillsA Review ResearchGate2017年8月29日 — grinding components in mills are balls Grinding balls are subject to repeated impacts and also to abrasive wear (in the case of wet grinding in aggressive oxidative media) Accordingly, they must be shatterresistant (stable under impact); and resistant to wear and corrosion [1–4] (Corrosion is a particular concern)Improving the Quality of Steel Grinding Balls Springer2Belgorod State Technological University named after VG Shukhov, Belgorod, Russia Abstract Ball mills for fine grinding cement clinker and additives are widely used around the world To improve the efficiency of a ball grinding the ball mills are transferred in closed circuit with airseparators of various designsAnalysis of the efficiency of the process in closed circuit

Wet Overflow Type Ball Mill and Applications

2024年1月12日 — How Overflow Type Ball Mill Works Material Feed: The raw material is fed into the mill at one end and travels through the mill by rotation The feed enters the mill at a specific rate, ensuring a controlled grinding process; Grinding Process: As the mill rotates, the grinding media crushes and grinds the material into a fine powder The wet 2023年12月28日 — 3 Moisture content of grinding materials Ball mill grinding can be divided into two methods: dry grinding and wet grinding For the dry grinding method, the grinding materials’ moisture content greatly influences the mill’s production and quality The higher the moisture content of the grinding materials, the easier it is to cause saturationFactors Affect The Output and Quality of Ball Mills And How 4 天之前 — Additionally, ball mills are used to grind materials like bentonite, kaolin, barite, and talc In ore processing, ball mills typically work alongside crushers, flotation machines, magnetic separators, and gravity separators 2 Cement grinding Cement ball mills are mainly used to grind clinker and gypsum into fine powder for cement productionHighquality Ball Mill with Low price for Kinds of MaterialsHigh Grinding Efficiency: The grinding mechanism of ball mills ensures effective comminution, resulting in high grinding efficiency and reduced processing time Easy Maintenance: Ball mills are relatively simple machines with fewer moving parts, making maintenance and repairs straightforwardBall Mill Grinding Machines: Working Principle, Types, Parts

How to promote the Efficiency of Ball Mill When Wet Grinding

2016年12月22日 — Ball mill can be divided into wet ball mill and dry ball mill Then how to promote the efficiency of ball mill when wet grinding? The lining of ball mill must have the advantages of high hardness The wet grinding and dispersing process defines your end product characteristics Our solutions include cuttingedge bead mills and threeroll mills, supported by unrivaled process and application expertise, to give you consistent, repeatable quality, every timeWet Grinding and Dispersing Equipment Bühler Group2024年9月3日 — REPLACEMENT OF WET BALL MILLING WITH HIGHPRESSURE GRINDING AHEAD OF MINERAL SEPARATION C Gagnon1, A Rosa1, S Makni1, and *R McIvor1 B Klein2, A Kumar2, F Wang2, D Gong2, and C Saud2 1COREM 1180 rue de la Minéralogie Quebec City, Quebec, Canada G1N 1X7 (*Corresponding author: This REPLACEMENT OF WET BALL MILLING WITH HIGHPRESSURE GRINDING 2020年7月15日 — Analysis and Implementation of the Method for Improving the Grinding Efficiency of Wet SemiAutomatic Mill in Gold Concentrator Zhongshan Ma 1, 2, 3 1 Qinghai Engineering Research Center for Gold Mineral Resource Development Dressing and Metallurgy Pilot Plant, Dulan, Qinghai , China 2Analysis and Implementation of the Method for

.jpg)

Industrial Ball Grinding Mill Machine

Grinding Mill Design Process Selection According to the china ball mill ore sample provided by the customer, the parameters of ore crushing and grinding are measured Through the simulation of JKSimMet computer 2019年11月1日 — The effect of the grinding time, the grinding media filling rate, and the powder filling rate on the grinding of lithium ore in a lab scale ball mill was investigated The results show that the grinding process of lithium ore is highly consistent with the nonfirst grinding kinetic equation, while the breakage rate decreases with the reduction Differences in dry and wet grinding with a high solid 2016年1月1日 — Ball mills for fine grinding cement clinker and additives are widely used around the world To improve the efficiency of a ball grinding the ball mills are transferred in closed circuit with air (PDF) Analysis of the efficiency of the grinding process in This difference is attributed to the power The power to drive a wet ball mill is said to be 30% lesser than that of a similar dry ball mill Nature Of Materials In the production of some products both wet ball and dry ball milling processes are requiredWet Ball Milling Vs Dry Ball Milling Orbis Machinery

The Influence of the Grinding Media Diameter on Grinding Efficiency

2024年6月14日 — The grinding process plays a crucial role in industry, allowing for the reduction of particle sizes of raw materials and substances to the required fineness—either as a finished product or for further technological processes The high demand for micro and nanopowders or suspensions is associated with the high energy consumption of the 2019年8月1日 — By comparison, the point load on the particles in ball mills is conducive to the attrition process (Bu et al, 2019b;Bu et al, 2020a) Abrasion and attrition result in rounder (more spherical Differences in dry and wet grinding with a high solid There are three types of grinding media that are commonly used in ball mills: • steel and other metal balls; • metal cylindrical bodies called cylpebs; • ceramic balls with regular or high density Steel and other metal balls are the most frequently used grinding media with sizes of the balls ranging from 10 to 150 mm in diameter [30]Grinding in Ball Mills: Modeling and Process Control2023年9月1日 — A wet ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the What is a wet overflow ball mill and its applications LinkedIn

.jpg)

Portable Silica Sand Ball Mill Wet Grinding Machine for Sale

1 天前 — Portable Silica Sand Ball Mill Wet Grinding Machine for Sale, Find Details and Price about Copper Ball Mill Portable Ball Mill from Portable Silica Sand Ball Mill Wet Grinding Machine for Sale Gongyi Hengchang Metallurgical Building Material Equipments Plant professional production team, quality control team, 10 years of export experience Combining impact and shearing actions enhances mill efficiency Proper selection of media milling equipment is vital for success in all three areas There are many different types of grinding mills (Table 1) Some devices, Solids Choose the Right Grinding MillRETSCH grinding mills for reliable size reduction tasks with a high degree of grindability for exact and fine results newest technology Learn more Equipment such as ball mills and disc mills use this grinding principle, where the action of the surfaces moving against each other results in size reduction through frictional forces Grinding Mills for reliable size reduction tasks RETSCH2000年1月1日 — The MaxxMill is a new type of stirred ball mill that differs widely from the stirred ball mills already available and used successfully in many applicationsMaxxMill dry and wet grinding with stirred ball mills in

.jpg)

EnergyMassSize balance model for dynamic control of

2016年3月3日 — to grinding process disturbances during transitions between various steadystates Also, the complex interactions within the mill circuit can be explored and evaluated with minimum cost and changes can then be made to the circuit to realise high efficiency and throughput The key elements required for accurate dynamic simulation are2024年9月10日 — Because the granularity of first stage ball mill is large, the impact force is great, and the wear is serious, so the magnetic liner is generally only suitable for the second stage ball mill Grinding medium of ball mill The grinding medium is essential for the ball mill, and the consumption is very largeHigh Efficiency China Stone Grinder Machine Ball Mill 3 天之前 — DOVE offers a wide range of high quality ball mills, for wet or dry grinding operations, as well as regrinding application, for capacities up to 240 Tons/HourBall Mill Ball Mills Wet Dry Grinding DOVE2023年11月24日 — The grinding efficiency of a ball mill is determined by the product size distribution, energy consumption, and the grinding costs Corrosive wear is greatly dominant in wet grinding when using ferrous grinding media and is responsible for up to 50% of The author discovered that lowdensity balls are less efficient than highdensity Grinding Media in Ball Mills for Mineral Processing

.jpg)

china high efficiency export south america ball mill

Ball Mill Suppliers Of China High Efficiency VCharty Ball Mill Ball mill is suitable for ore dressing, chemical, coal, cement and refractory sectors to operate fine grinding bearingtype drive ball mill is a technological changing type, compared with the traditional ball mill 15 lower operating current and reduce the starting current 50improve the phenomenon of Between 2021 and 2022 the exports of Balls, iron/steel, forged/stamped for grinding mills grew by 259%, from $133B to $167B Trade in Balls, iron/steel, forged/stamped for grinding mills represent 00071% of total world trade Balls, iron/steel, forged/stamped for grinding mills are a part of Other Iron ProductsBalls, iron/steel, forged/stamped for grinding mills2024年1月15日 — Ball milling is generally divided into dry milling and wet milling, wet milling is the most commonly used method with the advantage of high efficiency, and uniform particles out of millingDifference between “Dry Grinding” and “Wet Grinding” of Ball Mills2024年1月31日 — Ceramic ball milling has demonstrated remarkable energysaving efficiency in industrial applications However, there is a pressing need to enhance the grinding efficiency for coarse particles This paper Enhancing the Grinding Efficiency of a Magnetite

.jpg)

REPLACEMENT OF WET BALL MILLING WITH HIGH

Figure 4 CMM Ball Mill Feed Machine Grinding Rates With and Without Fines (9% Moisture) Thus, Functional Performance Analysis of the highpressure, opencircuit piston press testing provided the major discovery, and also quantified, that grinding efficiency on the coarse material (plus 150If you’re in the market for a ball mill, you’re likely looking for a reliable and highquality machine that can handle a wide range of materials and processesBall mills are used for grinding and mixing materials, and they can be found in a variety of industries, from mining and construction to pharmaceuticals and ceramicsA Comprehensive Guide to Finding the Best Ball Mill for Sale2020年11月13日 — The article introduces the difference between wet ball mill and dry ball mill in structure, working principle, machine features and application conditions easily fineness adjustment, high grinding efficiency, and low requirements for ore moisture content In addition, the material transportation device is simple, so the investment is about Dry Ball Mill VS Wet Ball Mill: What Are the Differences2019年11月1日 — Grinding was performed using a XMQΦ240 × 90 laboratoryscale conical ball mill (Wuhan Exploring Machinery Factory, Wuhan, China) The diameter and length of the intermediate cylinder part of mill were 240 and 90 mm, respectively (Fig 2)The operational speed was kept at 96 rpm (68% critical speed) according to the literature Differences in dry and wet grinding with a high solid

.jpg)

Circulation Mill System ZETA® Grinding Dispersing

5 天之前 — The highspeed mill system Zeta ® with improved peg grinding system optimizes your production capacity, energy demand and quality Designed for circulation operation and multipass operation, you achieve high throughput rates and high quality with a narrow particle size distribution for higher viscous products A minimal control expenditure is 2023年11月14日 — The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these millsA Review of the Grinding Media in Ball Mills for Mineral 2024年9月9日 — During production, the ball grinding machine may be called a cement mill, limestone ball mill, sand mill, coal mill, pebble mill, rotary ball mill, wet grinding mill, etc JXSC ball mills are designed for high capacity long service, and good quality matches Metso ball mills Grinding Media Grinding balls for mining usually adopt wet grinding Ball Mills Industry Grinder for Mineral Processing JXSC 2008年4月1日 — The ball size selection must be based on high energy efficient breakage of the coarsest particles for efficient grinding The changing mill geometry and operating parameters at constant kW, will High efficiency ball mill grinding ResearchGate

A New Approach to the Calculation of Bond Work Index with

2024年6月29日 — Grinding media influence the energy consumption and efficiency of the grinding process during the calculation of the Bond Work index (BWi), a wellknown method for selecting comminution equipment, evaluating milling efficiency, and calculating required milling power Traditional grinding tests often choose steel balls as the grinding media, 2024年1月13日 — Table 1 Chemical composition of typical grinding media (% wt) Adapted from [24] 211 Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in Grinding Media in Ball MillsA Review ResearchGate2017年8月29日 — grinding components in mills are balls Grinding balls are subject to repeated impacts and also to abrasive wear (in the case of wet grinding in aggressive oxidative media) Accordingly, they must be shatterresistant (stable under impact); and resistant to wear and corrosion [1–4] (Corrosion is a particular concern)Improving the Quality of Steel Grinding Balls Springer2Belgorod State Technological University named after VG Shukhov, Belgorod, Russia Abstract Ball mills for fine grinding cement clinker and additives are widely used around the world To improve the efficiency of a ball grinding the ball mills are transferred in closed circuit with airseparators of various designsAnalysis of the efficiency of the process in closed circuit

Wet Overflow Type Ball Mill and Applications

2024年1月12日 — How Overflow Type Ball Mill Works Material Feed: The raw material is fed into the mill at one end and travels through the mill by rotation The feed enters the mill at a specific rate, ensuring a controlled grinding process; Grinding Process: As the mill rotates, the grinding media crushes and grinds the material into a fine powder The wet 2023年12月28日 — 3 Moisture content of grinding materials Ball mill grinding can be divided into two methods: dry grinding and wet grinding For the dry grinding method, the grinding materials’ moisture content greatly influences the mill’s production and quality The higher the moisture content of the grinding materials, the easier it is to cause saturationFactors Affect The Output and Quality of Ball Mills And How 4 天之前 — Additionally, ball mills are used to grind materials like bentonite, kaolin, barite, and talc In ore processing, ball mills typically work alongside crushers, flotation machines, magnetic separators, and gravity separators 2 Cement grinding Cement ball mills are mainly used to grind clinker and gypsum into fine powder for cement productionHighquality Ball Mill with Low price for Kinds of MaterialsHigh Grinding Efficiency: The grinding mechanism of ball mills ensures effective comminution, resulting in high grinding efficiency and reduced processing time Easy Maintenance: Ball mills are relatively simple machines with fewer moving parts, making maintenance and repairs straightforwardBall Mill Grinding Machines: Working Principle, Types, Parts

How to promote the Efficiency of Ball Mill When Wet Grinding

2016年12月22日 — Ball mill can be divided into wet ball mill and dry ball mill Then how to promote the efficiency of ball mill when wet grinding? The lining of ball mill must have the advantages of high hardness The wet grinding and dispersing process defines your end product characteristics Our solutions include cuttingedge bead mills and threeroll mills, supported by unrivaled process and application expertise, to give you consistent, repeatable quality, every timeWet Grinding and Dispersing Equipment Bühler Group2024年9月3日 — REPLACEMENT OF WET BALL MILLING WITH HIGHPRESSURE GRINDING AHEAD OF MINERAL SEPARATION C Gagnon1, A Rosa1, S Makni1, and *R McIvor1 B Klein2, A Kumar2, F Wang2, D Gong2, and C Saud2 1COREM 1180 rue de la Minéralogie Quebec City, Quebec, Canada G1N 1X7 (*Corresponding author: This REPLACEMENT OF WET BALL MILLING WITH HIGHPRESSURE GRINDING

矿用机械世界排名

--碳酸钙粉磨青石磨粉机价格

--上海远通重钙磨粉机雷蒙机

--湖南石粉磨碎设备的销售

--导爆索制粉研磨设备厂家

--破石头用的立式磨那个牌子好

--汇科机械腻子粉机

--立式磨矿石磨粉机石墨上海90到180吨

--高细立磨中空网架

--预粉磨砂粉同出立磨常规碳酸钙砼

--磨粉机提升机构原理

--5t球磨机

--煤灰生产线厂家

--矿石雷磨矿石雷磨矿石雷磨

--雷蒙磨矿渣

--炭黑设备

--Cone Crushers With Drive System

--石墨炭黑价格

--白泥高岭土尧安矿在什么地方

--钬激光微粉磨的温度

--时产30吨无烟煤微粉磨

--华扬s240

--200TPH电解铝废渣磨粉机碳酸钙无烟煤粉碎站

--山东青州雷蒙磨厂

--非煤矿石灰石粉碎机建设试生产申请表

--贵阳矿石磨粉机多少钱一台

--莱驰 SM2000 北京

--一般石灰厂需要化工材料吗

--砌一方加气块需要多少水泥

--粗牙螺纹与细牙螺纹拧紧力矩

--