细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

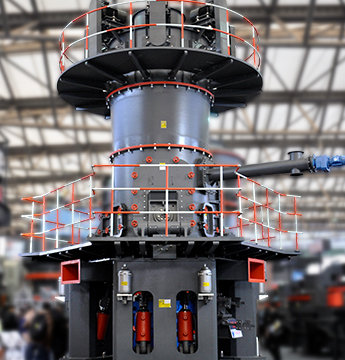

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Crushing In Limestone Mines

Limestone and Crushed Rock Department of Energy

2013年11月8日 — Limestone, one of the largest produced crushed rock, is a sedimentary rock composed mostly of the mineral calcite and comprising about 15 percent of the 2021年8月18日 — Blasting outcomes have significant impacts on downstream mining operations such as loading, hauling, crushing, milling, and mineral processing An ideal Optimization of BlastingAssociated Costs in Surface Mines 2020年2月18日 — The most widely adopted method of limestone mining is through opencast pits with bench formation Limestone mining causes widespread disturbance in the Environmental Hazards of Limestone Mining and Adaptive2016年9月1日 — Predicting the mean fragment size (50% passing size) in rock blasting is a critical component of mining operations because it directly affects downstream processes such as loading, hauling, and(PDF) Rock Fragmentation by Blasting – a review

Exploring the potential of late permian aggregate resources

2023年3月29日 — The characterizing attributes of the Wargal Limestone and Chhidru Formation include lower values of soundness, Los Angeles abrasion, aggregate impact, 2023年12月14日 — The results of the blasting experiments indicate that by controlling the size of the crushing zone and adjusting explosive performance, it is possible to significantly reduce fines content whileRock fragmentation size distribution control in 2022年12月1日 — Sadeghi et al (2020) used an artificial neural network and decision tree to predict the toe volume due to bench blasting using 100 blasting data of a limestone mine Minetocrusher policy: Planning of mine blasting patterns 2019年3月1日 — In the limestone quarry, measured dust concentrations were approximately 50% of concentrations measured at other quarries processing granitic rock material Dust emission from crushing of hard rock aggregates

Limestone Crushing And SandMaking Plant

2024年1月11日 — As an essential building material with a long mining history, limestone is the raw material for manufacturing cement, aggregates, lime, and calcium carbide in modern industry With the increasing demand for 2024年4月19日 — Atrition crushing is great for the production of very fine particle sizes and it is commonly used in mineral processing and mining for grinding ore Shear Crushing: Shear crushing takes a shearing force and Types of Crushers Explained: Everything You 2023年3月27日 — Limestone crushing is an essential part of the mining and construction industry Cone crusher parts are used for this purpose, and they come in various sizes and configurations to match different Do’s Don’ts Of Limestone Rock Crushing2013年1月1日 — Surface miner, a continuous mining machine, is being manufactured in India and abroad owing to enhanced demand of production in various mining industries like coal, limestone, gypsum, bauxite etc Different types of surface miners are manufactured today based on cutting drum placement and design specificationsRock excavation using surface miners: An overview of some

Optimization of BlastingAssociated Costs in Surface Mines

2021年8月18日 — Blasting outcomes have significant impacts on downstream mining operations such as loading, hauling, crushing, milling, and mineral processing An ideal blasting plan can result in decrease in undesirable blastinduced impacts and in supplementary costs of downstream operations This study developed a new 2021年7月15日 — Metallurgical studies for mines and miningspecific processes for problems, such as lump formation, chocking of silos, corrosion, wear and tear of equipment such as, ball mills, vertical roller mills, and roller press used in the crushing and grinding of limestoneModern Technological Applications for Limestone Mining2013年11月8日 — Energ9 y and Environmental Profile of the US Mining Industry Limestone and Crushed Rock Crushed rock is one of the most accessible natural resources and a major basic raw Stone preparation includes crushing screening, and washing it removes impurities Calcining is the heating of limestone to convert the calcium carbonate into Limestone and Crushed Rock Department of Energy2021年6月24日 — crushing process We are the world’s leading supplier of both unit machines and complete aggregates processing systems Comprehensive process solutions Your system may involve a whole series of processes, such as crushing and screening, conveying, classifying, washing and pretreatment, stockpiling, storage, loading and Crushing and Screening Handbook AusIMM

.jpg)

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 — Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by This paper attempts to evaluate the mineralogical and chemical composition of sedimentary limestone mine waste alongside its mineral carbonation potential The limestone mine wastes were recovered as the waste materials after mining and crushing processes and were analyzed for mineral, major and trace metal elements The major mineral Geochemical and mineralogical assessment of sedimentary limestone mine 2018年9月15日 — limestone and nearly 250,000 tons of dimensional limestone products generated in North America Data also reflects a diversity of operations with respect to size and location Respondents indicated net annual quarry production ranging from approximately 301 tons to 103,000 tons, while processors reported a Limestone Quarrying and Processing: A LifeCycle 2018年10月23日 — Mark Strebel explains how a dust control strategy in a limestone mine is preventing fugitive dust emissions Only a short drive from author Mark Twain’s boyhood home in the small town of Hannibal, Dust control strategy in limestone mine prevents

.jpg)

The Complete Guide to Primary Crushing,

2023年2月28日 — Gyratory crushers are often used in primary crushing for highcapacity crushing plants and are wellsuited for use in mines and quarries Impact crushers are ideal for producing highquality end 2019年1月18日 — InPit Crushing and Conveying (IPCC) systems are receiving more attention today due to current characteristics of openpit mining operations and what is expected to occur in the futureInpit crushing and conveying technology in openpit mining 2019年12月26日 — SILICA DUST SOURCES IN UNDERGROUND LIMESTONE MINES Gregory J Chekan and Jay F Colinet Pittsburgh Research Laboratory National Institute for Occupational Safety and Health crushing operations and to identify potential zones of high dust concentration Current dust controls for this study consisted of a 371 kw (50 hp) Silica Dust Sources in Underground Limestone Mines2024年7月17日 — Inside the crushing chamber, the material is repeatedly impacted by the blow bars and impact plates until it reaches the desired size and is discharged from the bottom Unlike cone crushers used for highhardness rocks, impact crushers are typically used for medium or fine crushing of mediumhard and brittle materials such as limestone Types of Crushers: Choosing the Right One for Each Stage

.jpg)

Benchmarking energy consumption for dump trucks in mines

2014年1月1日 — An energy benchmarking and bandwidth analysis for the US mining industry [11] showed that the practical minimum energy consumption was about 061 billion GJ/year whereas the energy consumption was 131 billion GJ/year in 2006 The bandwidth analysis estimates the minimum energy consumption of total mining industries including coal, 2023年10月23日 — province where there are a lot of limestone mining and crushing plants were selected for this study as shown in Fig 1 These selected mines are the openpit mines locating at 200 300 meters from PM Concentration Emitted from Blasting and Crushing intensity of basalt mining was roughly two times greater than limestone rock mining (3185 to 3572 kgCO 2eq/tonne of product) By scope, direct emission from transportrelated activities in both limestone and basalt rock mining was by far the largest source of emissions (4562%) compared to indirect emission from purchased gridelectricity Estimated Greenhouse Gases Emissions from Mobile and The additional crusher ensures the supply of High Grade Limestone to the cement plant in the coming years As it will be necessary to move the crusher in the future, Semen Bima has opted for a semimobile design of the crushing plant The plant capacity is 1000 t/h with a product grain size of 50 mmCrushing Technologies thyssenkrupp Polysius

.jpg)

Optimization of BlastingAssociated Costs in Surface

2021年11月10日 — Blasting operations in openpit mines account for about 30–40% of total mining costs The proportion of other costs due to secondary fragmentation, loading, hauling, safety, and crushing depends on a blasting plan (Bakhtavar et al, 2017) The success of a blasting plan primarily depends on proper drilling operation The main 2021年4月13日 — Inpit crushing and conveying (IPCC) systems have drawn attention to the modern mining industry due to the numerous benefits than conventional truckandshovel systems However, the implementation of A Framework for OpenPit Mine Production 2023年12月1日 — industry and mining were more highly exposed to crystalline silica4 Koelsch and Kaestle examined 82 workers in a shell limestone mine and concluded that limestone can cause pulmonary changes over a prolonged period under Background Dust exposure and its related harmful effects on miners is a serious health issue ObjectivesMonitoring and Assessment of Airborne Respirable Size reduction process begins with usage of explosives at the area for production of ore In later stages, the size reduction process performed with crushers before grinding in mills is called "crushing" Although there is no limit set, the downsizing process over 3 mm is considered as "crushing" and the ones below 3 mm are considered "grinding"WHAT IS THE CRUSHING PROCESS? MEKA

.jpg)

What Machines Do Stone Crushing Plants Need? Fote

2024年3月1日 — A cone crusher is a rock crusher used in the mining industry industry, industry for processing and production of nonmetallic materials Used in the mining industry for secondary crushing of stone, gold and other solid minerals Cone crushers have a coneshaped design that breaks larger rocks into smaller piecesKM Mining LLC specializes in processing and crushing of limestone and river rock for any project, large or small New construction, road base and oilfield locations are just the start! We have several different sizes of material available in both limestone and river rock, and our knowledgeable staff will help you determine the best aggregate KM Mining LLC Limestone and River Rock Quarries2014年4月15日 — This paper develops two optimal control models for the energy management of a mining crushing process based on jaw crushers The performance index for both models is defined as the energy cost to be minimized by accounting for the timeofuse electricity tariff The first model is referred to as a variable loadbased optimal control Optimal energy management for a jaw crushing process in deep mines2022年11月24日 — Limestone mining isn’t discussed as often as, say, fracking or oil drilling, but it has its fair share of risks and problems The dust comes from extracting the limestone as well as crushing and screening the limestone As the miners transport the limestone, dust can also escape into the environment along the travel pathWhat You Didn’t Know About Limestone Mining and the

Engineering Controls Database Best Practices for Dust

Figure 1 shows the plan view of a limestone crusher facility isolated from the other mine developments using stoppings and a blowing propeller fan to move dustladen air into the return Figure 1 Typical method used to isolate crushing facility from mine air Ventilate with a closed ventilation system2024年9月22日 — Authors: Kanokrat Makkwao, Tassanee Prueksasit Abstract: This study aimed to investigate PM 10 emitted from different limestone mines in Saraburi province, Thailand The blasting and crushing were the main processes selected for PM 10 sampling PM 10 was collected in two mines including, a limestone mine for cement manufacturing PM10 Concentration Emitted from Blasting and Crushing 2023年12月14日 — Deephole bench blasting is the primary method for aggregate extraction in mines However, factors such as complex geological conditions and suboptimal blasting parameters often result in uneven Rock fragmentation size distribution control in 4 天之前 — Tender document for “Supply and Installation of Water Supply Pipeline at Departmental crushing Screening Plant and Office area at Sanu Limestone Mines, Jaisalmer” Corrigendum1 Corrigendum2 Corrigendum3 Corrigendum4 1208RSMML Tenders

.jpg)

Excavation of Limestone SpringerLink

2021年7月15日 — Limestone is found near the surface (called a surficial deposit); hence, it is produced mainly from surface minesBy and large, limestone is mined by two methods: opencast stripping for hilly deposits and openpit mining for plain deposits To meet the industrial requirements of a large country like India, medium and smallsized mines of 2017年1月30日 — Mining, Crushing, Screening marketing of Limestone 1 The project is situated in western part Compliance report of EC/SanuI Limestone mineAprilSept 2016, RSMML 2 most of the period of summer season, thus, SPM values in summer season is much higher than the other seasons of the year Whereas NOx, SO2 CO are well Rajasthan State Mines minerals ltd Mining Sizing of 2020年2月5日 — 2110 “Mines Manager” shall mean the Mining Engineer so designated for SBUPCconcerning Sanu Limestone Mine of Rajasthan State Mines Minerals Ltd 2111 "Approved" shall mean approved in writing by the Company/ EngineerInCharge 2112 “Tender” shall mean the offer submitted by the tenderer or bidder against this inquiryRAJASTHAN STATE MINES MINERALS LIMITED RSMM2024年4月14日 — 22 Mining Limestone Using Surface Mining Methods 19 221 Excavation Methods The following are four applicable methods of the surface mining of limestone 1 Conventional method another form, allowing mining companies to get rid of primary crushing equipment The surface miner concept is not new It originated from civil Excavation of Limestone Springer

.jpg)

Rock Crushers Pulverizers Williams Crusher

Crushing may take place in one process with a single crusher However, secondary and tertiary crushing can be used to further break your material down to the desired size Many processing plants or rock crushing plants utilize several rock crushing stations to accommodate different material sizes and requirement Rock Crusher Applications2020年4月20日 — Why crushing? There are many practical purposes for industrial crushing Waste products get crushed so they for easier disposal and/or recycling You could crush wet materials, like cement, for use in construction and road building Crushing is also very useful in the chemical industry for breaking down hard materials such as limestone or coalCrushing in Mineral Processing Eastman Rock Crusher2022年12月1日 — The mining industry as an interdisciplinary activity exploited affordable minerals including gold, copper, coal, and others, in a challenging space through surface or underground mining A set of mining operations, including drilling, blasting, loading, hauling, crushing, and grinding, are linked together to break rock mass into valuable mineralsMinetocrusher policy: Planning of mine blasting patterns 2024年1月11日 — As an essential building material with a long mining history, limestone is the raw material for manufacturing cement, aggregates, lime, and calcium carbide in modern industry With the increasing demand for Limestone Crushing And SandMaking Plant

Types of Crushers Explained: Everything You

2024年4月19日 — Atrition crushing is great for the production of very fine particle sizes and it is commonly used in mineral processing and mining for grinding ore Shear Crushing: Shear crushing takes a shearing force and 2023年3月27日 — Limestone crushing is an essential part of the mining and construction industry Cone crusher parts are used for this purpose, and they come in various sizes and configurations to match different Do’s Don’ts Of Limestone Rock Crushing2013年1月1日 — Surface miner, a continuous mining machine, is being manufactured in India and abroad owing to enhanced demand of production in various mining industries like coal, limestone, gypsum, bauxite etc Different types of surface miners are manufactured today based on cutting drum placement and design specificationsRock excavation using surface miners: An overview of some 2021年8月18日 — Blasting outcomes have significant impacts on downstream mining operations such as loading, hauling, crushing, milling, and mineral processing An ideal blasting plan can result in decrease in undesirable blastinduced impacts and in supplementary costs of downstream operations This study developed a new Optimization of BlastingAssociated Costs in Surface Mines

Modern Technological Applications for Limestone Mining

2021年7月15日 — Metallurgical studies for mines and miningspecific processes for problems, such as lump formation, chocking of silos, corrosion, wear and tear of equipment such as, ball mills, vertical roller mills, and roller press used in the crushing and grinding of limestone2013年11月8日 — Energ9 y and Environmental Profile of the US Mining Industry Limestone and Crushed Rock Crushed rock is one of the most accessible natural resources and a major basic raw Stone preparation includes crushing screening, and washing it removes impurities Calcining is the heating of limestone to convert the calcium carbonate into Limestone and Crushed Rock Department of Energy2021年6月24日 — crushing process We are the world’s leading supplier of both unit machines and complete aggregates processing systems Comprehensive process solutions Your system may involve a whole series of processes, such as crushing and screening, conveying, classifying, washing and pretreatment, stockpiling, storage, loading and Crushing and Screening Handbook AusIMM2017年3月4日 — Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by (PDF) SIZE REDUCTION BY CRUSHING METHODS

Geochemical and mineralogical assessment of sedimentary limestone mine

This paper attempts to evaluate the mineralogical and chemical composition of sedimentary limestone mine waste alongside its mineral carbonation potential The limestone mine wastes were recovered as the waste materials after mining and crushing processes and were analyzed for mineral, major and trace metal elements The major mineral

新航机械厂白云石立磨磨粉机

--细石粉粉磨设备

--山西太原市白云石磨粉设备环保智能

--方解石矿尾矿品位20进行回收能到多少品位

--河北石家庄市白云石雷蒙磨运行稳定

--研磨石灰石粉磨设备

--英安岩中速磨粉设备

--中小型矿石磨粉机

--蓝晶石研磨机械工作原理

--什么是矿山环辊磨

--山西太原锂辉石粉销售点

--立磨构造和操作立磨构造和操作立磨构造和操作

--碳酸钙粉磨粉碎粉磨系统站产量950T H

--时产1200吨石膏微粉磨

--石灰石场属于什么设施

--翡翠 解石机

--输送机皮带打滑声音

--生石灰熟化机

--立式磨机转速

--鄂温克族旗皮带输送机

--雷蒙磨唐山产

--帆钛炼钢对环境影响

--石材工具大全

--时产80吨中速磨粉机械

--锂矿磨粉机制矿粉用哪种机器较适宜?

--80目120目检验筛相当于多数毫米

--隐晶石墨厂家

--广西辉绿岩分布

--长沙粉碎设备方解石石灰石制粉生产线

--临沂硫磺加工机器山东临沂产业带

--