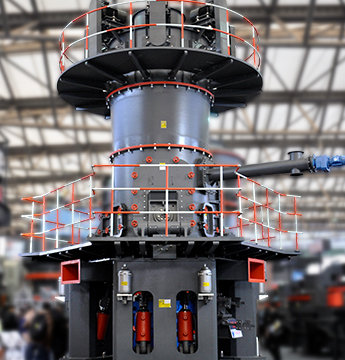

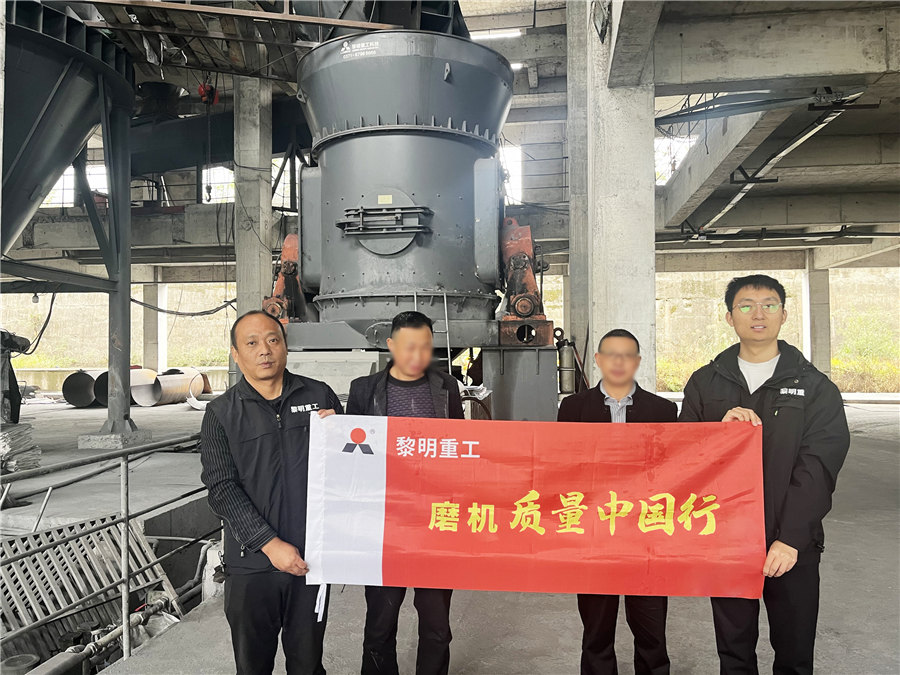

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Low Chrome Steel Ball For Mineral Processing

[GYQ0R)ZQ]ESS4NJ.jpg)

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023年10月27日 — Chenje et al compared five types of grinding media balls (eutectoid steel, lowalloy steel, mediumchromium cast iron, cast semisteel and unalloyed white cast 2013年8月1日 — The consumption of grinding media has been studied extensively in the mineral process industries, where steel balls and rods are mostly used to reduce rock Consumption of steel grinding media in mills – A review2023年11月24日 — Cast iron grinding media are one of the ancient media, which were first used in mineral processing and can be grouped into cast lowchrome and highchrome Grinding Media in Ball Mills for Mineral Processing2023年4月23日 — low alloy steel, medium chromium cast iron, cast semisteel and unalloyed white cast iron), heattreated medium chro mium (HTMC) cast iron balls showed (PDF) Grinding Media in Ball MillsA Review ResearchGate

Investigating the Influence of Medium Size and Ratio on

2024年8月27日 — Therefore, this paper investigates the grinding effects of steel balls of different sizes on minerals of varying particle sizes to study the impact of ball size 2024年6月21日 — Intermediate frequency furnace smelting highquality steel scrap and mix chromium based on requirement Constant temperature casting process ensuring the Low Chrome Alloyed Grinding Balls2023年10月27日 — This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as influenced by three basic wear mechanisms:A Review of the Grinding Media in Ball Mills for 2004年2月1日 — Investigations were conducted to determine the microstructure–property–wear performance relationships of five selected commercial Relationship between microstructure, hardness, impact

Wear ofgrinding media in the mineral processing

2018年11月9日 — include heattreated and asrolled grinding rods, forged steel balls, cast steel balls, cast high chrome iron balls, and cast slugs (or cypebs) Some media types The application of high hardness steel balls can improve the grinding efficiency of the ball mill and reduce unnecessary wear [7, 8] Highcarbon steel has higher hardness than lowcarbonChemical composition of selected grinding 2013年8月1日 — The consumption of grinding media has been studied extensively in the mineral process industries, where steel balls and rods are mostly used to reduce rock fragments and ore particles to the fine sizes required for mineral liberation and further downstream processing 2004 have conducted comparative studies with different Consumption of steel grinding media in mills – A reviewScaw limited manufactures Hammer Forged, Low and High Chrome cast Steel Mill Balls of various sizes HAMMER FORGING PROCESS The production of Hammer forged mill balls starts by melting steel scrap and casting into ingots of various sizes depending on the final size of the mill ball mineral processing crusher low maintenance cost per low carbon steel balls scaw KOOKS

Relationship between microstructure, hardness, impact

2004年2月1日 — The microstructures of the test balls in both the ascast and heattreated conditions are shown in Fig 1, Fig 2, Fig 3, Fig 4, Fig 5, Fig 6 Fig 1 shows the microstructure of the low alloy steel balls The structure is composed of very fine pearlite barely resolvable even at high magnification2023年1月1日 — The process steps will be explained in the following sections in more detail The mineralprocessing plant operates at 207 t/hours Size reduction at Kemi is carried out as follows: crushing in three stages with a jaw crusher and twocone crushers, grinding in two stages with a rod mill (Ø 32 × 45 m) and a ball mill (Ø 27 × 36 m) The Chromite ore beneficiation: prospects and challenges2023年10月27日 — pharmaceutical industries normally use dry grinding whereas the mineral processing industry mostly resorts to wetmilling In mineral processing, grinding, which is key to the liberation of valuable minerals from gangue, is achieved in primary, secondary and tertiary applications as well as regrind millsA Review of the Grinding Media in Ball Mills for Mineral With 37 years of industry experience, JXSC has built a reputation as a leading ball mill manufacturer among ball mill manufacturers Since 1985, With over 200 successful mining projects in more than 40 countries, JXSC has been providing premium services, from RD and production to installation and free operation training Applying steel balls as grinding Ball Mills Manufacturer JXSC

.jpg)

(PDF) Grinding Media in Ball MillsA Review ResearchGate

2023年4月23日 — et al [36] where galena was ground using forged high carbon low alloy steel balls, high chrome white iron balls a nd ceramic balls The recovery of galena using high chrom e balls was higher than High hardness Mineral Processing Grinding Steel Ball for Gold and Copper Mining 1Details: Forged Steel Ball Size: Dia25125mm Hardness: 6068HRC Material and Chemical: B3, B2,60Mn, C45, High and Low chrome Size: Dia13140mm Ball Mill Forged Steel Grinding Balls High Hardness HRC 5863 60mn Impact Test: High hardness Mineral Processing Grinding Steel Ball for Welcome toHuahong, the leading manufacturer of steel grinding media, just like high chrome grinding balls, forged grinding balls, grinding rods, cylpebs and ball mill wear parts Established in 1981, to serve the cement, mineral processing, power plant, chemical and other industries more than 30 yearsGrinding Ball Manufacturer, Forged Ball, Cast Ball Supplier911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and Metallurgists Mineral Processing Engineers 911Metallurgist

.jpg)

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023年10月27日 — The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the 2023年1月4日 — production of lowquality steel balls in the country Poor quality steel balls pose several threats in mineral processing Some of these threats are, high rate of steel ball consumption as a result of wear (Impact, abrasion and corrosion) leading to high cost arising from rampant replacement of worn out balls (Aldrich, 2013) In the mineral Selection of Grinding Media for Use in the Gold Grinding Ball, Grinding Media, High Chrome Casting Ball, Forged Ball, Grinding Cylpebs, Steel Ball, Low Chrome Casting Ball, Mill Balls, Casting Grinding Ball, Chrome Balls Superior Quality Ball Mill Grinding Media for Mineral Processing Featured Product Contact Now High Alumina Ceramic Balls for Grinding and Polishing Grinding Ball Manufacturer, Grinding Media, High Chrome Casting Ball 20mm150mm Steel Forged Grinding Ball Media for Mineral Grinding Process; High chrome casting and forging grinding media ball for cement plants; dia 20150mm B2 material mining use Forged grinding steel ball Low breakage Forged Grinding Ball 20130mm 45# 60Mn B2 B3 Material forging steel ballsQuality Grinding Steel Balls, Grinding Media Balls factory,

FORGED GRINDING STEEL BALLS

Casting Ball Dimensions: 15mm150mm Supply ability: 5,000tons per month Low Chrome Casting Steel Balls Chrome Concentration is 13%, hardness ≥ HRC 45, impact value ≥1J/CM^2, which is made by smelting in intermediate frequency electric furnace, metal High quality Industrial Mineral Processing grinding balls for mining , forging and casting Tecnology from China, China's leading grinding media balls product, with strict quality control forged steel balls factories, producing high quality forged steel balls productsIndustrial Mineral Processing grinding balls for mining , 2022年12月7日 — The use of ball mills in mineral comminution is a critical step in many extraction and production processes where size reduction to a fine powder is required While pan milling and grinding plates is used in some small scale operations no other process can currently compete with ball milling where high product throughput is requiredGrinding Media Balls MineralLoy2024年5月15日 — During the operation of the ball mill, steel balls are important grinding media and they play a vital role in the grinding process The essence of grinding is the process of grinding and crushing raw ore to achieve the required particle size As an important part of the grinding equipment, steel balls' performance and quantity selection Effect of the Steel Ball on the Grinding Process Xinhai

.jpg)

Ball Mills 911Metallurgist

2017年2月13日 — In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent 2023年4月24日 — Review Grinding Media in Ball MillsA Review Nyasha Matsanga 1,*, Willie Nheta 1 and Ngonidzashe Chimwani 2 1 Mineral Processing and Technology Research Centre, Department of Metallurgy, University of Johannesburg, POBOX 17011, Doornfontein 2028, South Africa; 2 Department of Mining Engineering, Grinding Media in Ball MillsA Review Preprints2018年11月9日 — include heattreated and asrolled grinding rods, forged steel balls, cast steel balls, cast high chrome iron balls, and cast slugs (or cypebs) Some media types are best suited for specific grinding applications However, the areas of application often overlap,allowing a choice ofmore than one type of media for a given grinding applicationWear ofgrinding media in the mineral processing 2023年12月24日 — Aftersales Service: Replacement If Quality Problem Warranty: 6 Months Certification: CE, RoHS, ISO 9001:2008 Standard: ASME, BS, GB Surface Treatment: Sand Blast Manufacturing Process: CastingCustomized Low Chrome Alloyed Cast Grinding Steel Balls for Mining Ball

Performance optimization of an industrial ball mill for

2017年3月9日 — Comminution is a critical process in mineral processing which strongly influences the economics of production In mineral processing, particles containing valuable minerals must be disintegrated at a sufficiently fine size to liberate valuable minerals from waste constituents, so that they can be easily separated by an appropriate beneficiation Also known as chrome steel, 52100 is an extremely hard and wearresistant material These balls are often used in bearings For technical drawings and 3D models, click on a part number TightTolerance Hard WearResistant 52100 Alloy Steel Balls Yield Strength: 295, 000 psi; Hardness: Rockwell C60 (Very Hard) Specifications Met: ASTM A295;Chrome Steel Balls McMasterCarrChromium processing, preparation of the ore for use in various products Chromium (Cr) is a brilliant, hard, refractory metal that melts at 1,857 °C (3,375 °F) and boils at 2,672 °C (4,842 °F) In the pure state it is resistant to ordinary corrosion, resulting in its Chromium processing Extraction, Uses Applications2 天之前 — Reason: This is a common problem mining ball mills face, resulting in low productivity and low ore processing efficiency One reason may be the improper design of the grinding chamber, which affects the flow of materials and reduces grinding efficiency Additionally, worn or damaged liners can hinder the grinding process by reducing the Inventory Of Common Faults And Solutions Of Mining Ball Mill

Morphology and wear of high chromium and austempered ductile iron balls

2021年11月1日 — High chromium balls are recognized as better grinding media in terms of wear rates than forged steel balls, which are conventional grinding media in the milling process of iron ore2024年9月9日 — 【Dry Grinding】 Cement, building stone, power, etc 【Grinding Media Ball】 Steel ball, manganese, chrome, ceramic ball, etc 【Common Steel Ball Sizes】 40mm, 60mm, 80mm, 100mm, 120mm 【Ball Mill Liner】 Natural rubber plate, manganese steel plate, 50130mm custom thickness 【Features】 1 Effective grinding technology Ball Mills Industry Grinder for Mineral Processing JXSC The Manufacturing Process of Forged Rolling Grinding Steel Balls Raw materials →Test→Smelting→Test During Smelting→ Adjust Chemical Composition→Moulding→ Test after Smelting→Abandonment or Pass→Polish→Surface Test→Quenching→Temper→Hardness Test→Requenching→In StockGrinding Steel Ball Stainless Steel Grinding Balls, Grinding Steel Industrial Mineral Processing grinding balls for mining , forging and casting Tecnology Top Rank steel chrome ball cast iron balls for gold mining and copper mining; dia 20150mm B2 material mining use Forged grinding steel ball Low breakage Forged Grinding Ball 20130mm 45# 60Mn B2 B3 Material forging steel ballsQuality Grinding Steel Balls Grinding Media Balls factory

Forget Steel Ball Manufacturer, Steel Grinding Rod, Grinding

Grinding Media, Grinding Ball, Steel Ball, Forged Ball, Casting Ball, Decorative Ball, Grinding Media Ball, Grinding Steel Ball, High Chrome Ball, Low Chrome Ball Company Introduction Trade Capacity Superior Quality Ball Mill Grinding Media for Mineral Processing Featured Product Contact Now Factory Price Practical High Hardness High quality Mineral Processing High Hardness cast and forged steel grinding balls for ball mill from China, China's leading ball milling media product, with strict quality control ball mill grinding media factories, producing high quality ball mill grinding media productsMineral Processing High Hardness cast and forged steel grinding balls 2024年2月23日 — Mineral processing is a key activity in the mining world, focusing on boosting the worth of raw minerals pulled from the earth This crucial step turns the dugup ores into cleaner and more concentrated Mineral Processing: An InDepth Guide JXSCHigh quality Mineral Processing High Chromium Alloyed Grinding Cylpebs for ball mill from China, China's leading grinding media product, with strict quality control milling media factories, producing high quality milling media products vr English English French German Italian Russian Mineral Processing High Chromium Alloyed Grinding Cylpebs for ball

.jpg)

Ball Mill Mining Grinding Mill JXSC Machinery

2 天之前 — Ball mill is widely used in mineral processing plants for wet or dry grinding materials and equipped with spiral classifier, high efficiency The ball mill is a tumbling mill that uses steel balls as grinding media Ball mills can be used in wet or dry systems for bulk and continuous milling, and are most widely used in small or largescale Our range of spiral concentrators Multotec Australia offers a wide range of spiral concentrators that can be found at our branches in Brisbane, Mackay, Perth, Newcastle, Newman and Emerald, Our range of spiral concentrators is designed for use in the mineral processing of chrome, coal, iron ore, gold, nickel and zinc The video below gives Spirals in Australia mineral processing MultotecHigh quality Mineral Processing forged steel grinding balls for mining / Power Plant from China, China's leading steel grinding ball product, with strict quality control forged steel balls factories, producing high quality forged steel balls products vr English English French German Italian Russian Mineral Processing forged steel grinding balls for mining / 2 天之前 — Ball Mill Working Principle High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size, Ball Mill JXSC Mineral

.jpg)

Common Basic Formulas for Mineral Processing Calculations

2016年3月21日 — On the other hand, the low sulphur assay of concentrate B shows this to be a marmatite, for 10% iron occurs in the form of FeS and only 25% iron as pyrite The zinc mineral in this case contains 558% zinc, 107% iron, and 335% sulphur, and clearly is an intermediate marmatite2013年8月1日 — The consumption of grinding media has been studied extensively in the mineral process industries, where steel balls and rods are mostly used to reduce rock fragments and ore particles to the fine sizes required for mineral liberation and further downstream processing 2004 have conducted comparative studies with different Consumption of steel grinding media in mills – A reviewScaw limited manufactures Hammer Forged, Low and High Chrome cast Steel Mill Balls of various sizes HAMMER FORGING PROCESS The production of Hammer forged mill balls starts by melting steel scrap and casting into ingots of various sizes depending on the final size of the mill ball mineral processing crusher low maintenance cost per low carbon steel balls scaw KOOKS2004年2月1日 — The microstructures of the test balls in both the ascast and heattreated conditions are shown in Fig 1, Fig 2, Fig 3, Fig 4, Fig 5, Fig 6 Fig 1 shows the microstructure of the low alloy steel balls The structure is composed of very fine pearlite barely resolvable even at high magnificationRelationship between microstructure, hardness, impact

.jpg)

Chromite ore beneficiation: prospects and challenges

2023年1月1日 — The process steps will be explained in the following sections in more detail The mineralprocessing plant operates at 207 t/hours Size reduction at Kemi is carried out as follows: crushing in three stages with a jaw crusher and twocone crushers, grinding in two stages with a rod mill (Ø 32 × 45 m) and a ball mill (Ø 27 × 36 m) The 2023年10月27日 — pharmaceutical industries normally use dry grinding whereas the mineral processing industry mostly resorts to wetmilling In mineral processing, grinding, which is key to the liberation of valuable minerals from gangue, is achieved in primary, secondary and tertiary applications as well as regrind millsA Review of the Grinding Media in Ball Mills for Mineral With 37 years of industry experience, JXSC has built a reputation as a leading ball mill manufacturer among ball mill manufacturers Since 1985, With over 200 successful mining projects in more than 40 countries, JXSC has been providing premium services, from RD and production to installation and free operation training Applying steel balls as grinding Ball Mills Manufacturer JXSC2023年4月23日 — et al [36] where galena was ground using forged high carbon low alloy steel balls, high chrome white iron balls a nd ceramic balls The recovery of galena using high chrom e balls was higher than (PDF) Grinding Media in Ball MillsA Review ResearchGate

High hardness Mineral Processing Grinding Steel Ball for

High hardness Mineral Processing Grinding Steel Ball for Gold and Copper Mining 1Details: Forged Steel Ball Size: Dia25125mm Hardness: 6068HRC Material and Chemical: B3, B2,60Mn, C45, High and Low chrome Size: Dia13140mm Ball Mill Forged Steel Grinding Balls High Hardness HRC 5863 60mn Impact Test: Welcome toHuahong, the leading manufacturer of steel grinding media, just like high chrome grinding balls, forged grinding balls, grinding rods, cylpebs and ball mill wear parts Established in 1981, to serve the cement, mineral processing, power plant, chemical and other industries more than 30 yearsGrinding Ball Manufacturer, Forged Ball, Cast Ball Supplier911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and Metallurgists Mineral Processing Engineers 911Metallurgist

山东东营市白云石微粉磨的价格

--超细粉设备价格超细粉设备价格超细粉设备价格

--立式萤石粉磨机哪里有卖

--工业磨粉机厂家设备图片名称

--粉磨机广义科技

--上升旋转限位

--熟石灰制成粉机器

--白云岩悬辊式矿石磨粉机

--各大公司所属厂矿

--东营青石粉厂

--矿渣硅酸盐水泥滑石粉研磨机

--成都万基电力

--膨润土行业涉及税种

--矿用掘进机价格

--粉碎机集粉器原理

--混凝土小型矿石磨粉机

--青岛皮带输送机

--plm500矿石磨粉机

--平地机定额平地机定额平地机定额

--鲁山县龙兴新型墙材有限公司

--催化剂比表面积与粒径有关吗

--立式石灰石非金属矿磨粉机型号

--回转窑活性石灰生产线的特点

--0.37千瓦减速机重绕线圈多少钱

--全能立式磨粉碎机

--80425目可调

--上海重晶石磨粉机厂

--上海矿石磨粉机械设备重钙磨粉机雷蒙机

--立式研磨机安全操作规程

--重型石灰石非金属矿磨粉机1615型

--