细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

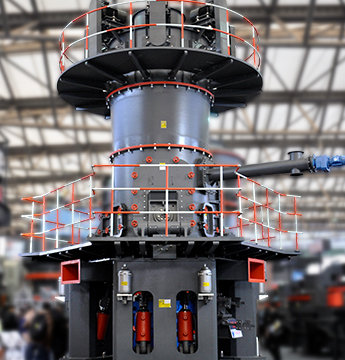

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Cement Grinding Vertical Roller Mills

.jpg)

Vertical roller mills Cement

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the 2021年1月1日 — With the grinding capacity of a vertical roller mill and the ability to dry, grind and sort in a single unit, the vertical roller mill offers a definite advantage over the ball Review on vertical roller mill in cement industry its 2017年9月11日 — Abstract: In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the(PDF) Performance Evaluation of Vertical Roller For raw material grinding a quadropol® vertical roller mills QMR² 45/23 was contracted to serve the kiln line, while for cement grinding two identical QMC² 45/23 were considered for grinding different cement types The quadropol® thyssenkrupp Polysius Grinding

PROCESS CONTROL FOR CEMENT GRINDING IN

2017年10月27日 — The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process 2022年4月4日 — The quadropol® vertical roller mill by thyssenkrupp Industrial Solutions takes a holistic approach to modern grinding systems in terms of its simple and VERTICAL ROLLER MILLS A holistic VRM approach2021年1月1日 — Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption, Review on vertical roller mill in cement industry its 2013年3月13日 — of initial TRM604 Raw Vertical Roller Mill, and enter into supply contract with Hebei Kuangfeng Cement Co, Ltd Such vertical roller mill is the biggest one for raw TRM SERIES CEMENT VERTICAL ROLLER MILLTRM

.jpg)

SikaGrind® for vertical roller mills

5 天之前 — The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate, energy 2022年5月9日 — The raw materials were mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The raw vertical roller mill has four rollers, 3000 KW main drive, 48 m table diameter, 2 Modeling of energy consumption factors for an industrial cement 2013年5月1日 — According to the research on the fine grinding process of vertical roller mill to produce cement by Liu et al (2013), the particle size distribution can be more uniform than the average size on Study on Particle Characteristics of Cement by Vertical Roller Mill For raw material grinding a quadropol® vertical roller mills QMR² 45/23 was contracted to serve the kiln line, while for cement grinding two identical QMC² 45/23 were considered for grinding different cement types The quadropol® thyssenkrupp Polysius Grinding

Cement Grinding Cement Plant Optimization

Cement grinding operation may be performed in one of the following mill setups Ball and tube mills Vertical Roller Mills (VRM) Roller press with Ball mill Ball Mill Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, Croatia MPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil Turkey Tracim, Turkey MPS 5300 B mill for cement raw material grinding, CDI Hail Cement, Saudi Arabia Any questions concerning our services Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsThe working principle and structure of lowvibration vertical roller mills and forces of key component were analyzed intelligently and based on the intelligent numeral calculations, the maximum stresses of three key components were much lower than the yield strength of materials and the rocker armroller system of the proposed lowVibration Vertical mill is [PDF] Cement grindinga comparison between vertical roller mill 2017年10月27日 — The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and PROCESS CONTROL FOR CEMENT GRINDING IN

.jpg)

Cement Grinding Machine Selection: Vertical Roller Mill VS Roller Press

The particle shape of the materials from the roller press and the vertical roller mill is also different The vertical mill grinds the material by two forces, the extrusion force and the shearing force between the roller and the grinding disc; the roller press grinds the material by only one force, the force between the two grinding rollers2024年9月17日 — Cement Industry LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology The roller grinding mill technology, patented in 1928 and continuously developed since then, has become synonymous with Loesche‘s pioneering engineering knowhowCement Industry Loesche2015年10月23日 — Energyefficient equipments such as highpressure grinding rolls, vertical roller mills, CKP pregrinders, Cemex ® mills and Horomills ® are used at both finish grinding of cement and raw materialgrinding stages due to higher energy consumption of conventional multicompartment ball milling circuits Multicompartment ball mills can be EnergyEfficient Technologies in Cement Grinding2021年4月27日 — OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinder s with ball mills Ball mills have been the traditional method of comminution in the mineral OPTIMIZATION OF CEMENT GRINDING OPERATION IN

.jpg)

Vertical roller mill vs ball mill for cement grinding:

The choice between a vertical roller mill and a ball mill for cement grinding ultimately depends on the specific needs and constraints of the cement plant VRMs offer significant energy savings, finer product control, and reduced maintenance costs, making them an attractive option for modern cement plants focused on efficiency and sustainability2016年1月23日 — grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system However, despite these benefits, applications of the vertical roller mill for cement grinding are less prevalentCement grinding Vertical roller mills versus ball millsFor several decades the cement industry has successfully utilized vertical roller mills (VRM) for grinding of raw materials and solid fuels Most recently, this technology has been employed for Operational experience from the United States' first vertical roller MVR vertical roller mill with conventional planetary gearbox is the optimum solution from Pfeiffer in terms of economy for small to medium throughput rates MVR 6000 C6 with planetary gearbox for cement grinding, Lafarge North America Ravena, USA MVR 6000 C6 with planetary gearbox for cement grinding, Shree Cement Raipur, IndiaCement mills and raw mills for small to medium throughput

Vertical Roller Mill Grinding Roller AGICO Cement Plant

AGICO VRM Grinding Roller After decades of continuous improvement and improvement, the vertical roller mill has been widely used in the field of cement raw meal, coal powder, and slag grinding The grinding roll is a key component in the vertical roller mill, and it is also the most worn in the daily operation of the mill2017年4月1日 — Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding Operational parameters affecting the vertical roller mill 2024年5月24日 — The first significant use of the vertical roller mill for cement grinding can be traced back to the 1970s Initially, these mills were used in raw material grinding, but their potential for The Evolution of Clinker Vertical Roller Mills: From Inception 2022年7月26日 — CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS Pilot Mill (Picture: Loesche GmbH, Germany) The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate energy saving ́ Higher fineness faster strength development ́ Reduced vibration Picture: Loesche GmbH, Germany CEMENT SikaGrind®

Study on Particle Characteristics of Cement by Vertical Roller Mill

2013年5月1日 — The particle characters and their physical properties of vertical roller mill finish grinding cements were studied in this paper The difference with roller pressball mill combined grinding products was also analysis The results were shown that the particle size of the vertical roller mill finish grinding cements was more evenly distributed at the This paper proposed a controller design method based on expert PID to automatically control the load and quality of cement vertical mill This method is applied to a cement plant in Guangxi Province The operation results show that the designed controller can ensure the stability of the system to increase the cement output and reduce energy consumption Expert PID Control of Grinding Condition for Cement Vertical Roller Mill2024年1月3日 — Keywords: Vertical roller mill, cement grinding, performance evaluation INTRODUCTION Cement production is highly energy consuming process with energy utilization of around 110150 kWh/t (Villa,Performance Evaluation of Vertical Roller Mill in Cement Today, we continue to use our curiosity and innovative approach to discover new ways to optimise equipment and processes We are especially active in bringing the advantages of digitalisation to the cement industry Our experience in automating cement plants has given us a head start on harnessing the potential of digital technologiesPremium solutions for the cement industry

.jpg)

2006 Slag Grinding With MPS Vertical Roller Mills PDF Mill

2014年7月23日 — The document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag content Currently an MPS 5600 BC able to produce 120t/h of slag at 5000cm2/g fineness is being installed The MPS series 2023年8月17日 — has supplied the global cement industry with leading Vertical Roller Mill (VRM) designs for raw, fuel and cement grinding for several decades The OK™ mill has been ’s standard cement VRM since 1993 Since its introduction, the OK mill has proven to be the most efficient cementOK™ mill The most reliable and efficient mill for raw and This article will explore the application of vertical roller mills in the cement industry, including their benefits, efficiency, and ecofriendly features Understanding Vertical Roller Mill Technology Vertical roller mill (VRM) is a type of grinding machine used to grind materials into extremely fine powder, commonly used in the cement industryApplication of Vertical Roller Mill in Cement ProductionOf the 4 main mill systems in use for cement grinding, ball mills are by far the predominant, despite a higher energy consumption compared with a standalone Vertical Roller Mill or Roller Press; 2 Beside historical reason, ball mills are generally more reliable, simpler to operate maintain, the wear parts readily available stocking cost Improvements in New Existing Cement Grinding Mills by

CFB石灰石脱硫剂制备64.jpg)

ATOX® Coal Mill Cement

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeFor several decades the cement industry has successfully utilized vertical roller mills (VRM) for grinding of raw materials and solid fuels Most recently, this technology has been employed for the combination of Portland cement, blended cements and slag cements The VRM offers several benefits compared to the ball mill in regards to operating costs and Operational experience from the United States' first vertical roller 2017年8月12日 — vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and mostPROCESS OPTIMISATION FOR LOESCHE GRINDING Vertical roller mills PFISTER® Feeding and dosing This 3day seminar covers ball and vertical mills with a focus oncomminution theory, design basis, operational principles, control and regulation, process troubleshooting, calculation methods, and optimization cement plants Work sessions are scheduled to allow for an interactive Cement Production Seminar: Grinding Cement

.jpg)

Limestone VRM Vertical Roller Mill In Cement

High Efficiency Limestone Desulfurization Vertical Grinding Mill Production Line Limestone Price For Sale Description HVM vertical mill is a product that Hengcheng Technology actively absorbs foreign successful Vertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as VRM In Cement Plant Maximize Energy Saving CNBM 2024年9月23日 — A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for Energysaving and Efficient Vertical Roller Mill Fote Machinery2014年10月1日 — Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, manganese, magnesite, feldspar and titaniumCopper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant

TRM SERIES CEMENT VERTICAL ROLLER MILL TRM

2013年3月13日 — for cement grinding based on TRM series Raw Vertical Roller Mill The initial TRMK4541 Cement Vertical Roller Mill was operated in Vietnam Phuc Son Cement Co, Ltd in June of 20102023年12月6日 — mills for cement grinding, a 245 tph vertical roller mill was added A Technical Concept The rating of the modular vertical roller mill 5000 R4 mill is based on grinding tests conducted at the Grinding Process Optimization Featuring Case Studies 2016年10月5日 — In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equip‐ ments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study EnergyEfficient Technologies in Cement Grinding2023年7月4日 — A cement vertical roller mill (VRM) is a type of grinding equipment commonly used in cement plants for raw material grinding and cement grinding It is an energyefficient alternative to traditional ball mills, as it utilizes rollers to grind and crush the materials between a rotating grinding table and a set of rollers mounted on a vertical axisVertical Roller Mill in Cement Manufacturing Plant

Modeling of energy consumption factors for an industrial cement

2022年5月9日 — The raw materials were mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The raw vertical roller mill has four rollers, 3000 KW main drive, 48 m table diameter, 2 2013年5月1日 — According to the research on the fine grinding process of vertical roller mill to produce cement by Liu et al (2013), the particle size distribution can be more uniform than the average size on Study on Particle Characteristics of Cement by Vertical Roller Mill For raw material grinding a quadropol® vertical roller mills QMR² 45/23 was contracted to serve the kiln line, while for cement grinding two identical QMC² 45/23 were considered for grinding different cement types The quadropol® thyssenkrupp Polysius Grinding Cement grinding operation may be performed in one of the following mill setups Ball and tube mills Vertical Roller Mills (VRM) Roller press with Ball mill Ball Mill Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical Cement Grinding Cement Plant Optimization

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, Croatia MPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil Turkey Tracim, Turkey MPS 5300 B mill for cement raw material grinding, CDI Hail Cement, Saudi Arabia Any questions concerning our services The working principle and structure of lowvibration vertical roller mills and forces of key component were analyzed intelligently and based on the intelligent numeral calculations, the maximum stresses of three key components were much lower than the yield strength of materials and the rocker armroller system of the proposed lowVibration Vertical mill is [PDF] Cement grindinga comparison between vertical roller mill 2017年10月27日 — The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and PROCESS CONTROL FOR CEMENT GRINDING IN The particle shape of the materials from the roller press and the vertical roller mill is also different The vertical mill grinds the material by two forces, the extrusion force and the shearing force between the roller and the grinding disc; the roller press grinds the material by only one force, the force between the two grinding rollersCement Grinding Machine Selection: Vertical Roller Mill VS Roller Press

Cement Industry Loesche

2024年9月17日 — Cement Industry LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology The roller grinding mill technology, patented in 1928 and continuously developed since then, has become synonymous with Loesche‘s pioneering engineering knowhow2015年10月23日 — Energyefficient equipments such as highpressure grinding rolls, vertical roller mills, CKP pregrinders, Cemex ® mills and Horomills ® are used at both finish grinding of cement and raw materialgrinding stages due to higher energy consumption of conventional multicompartment ball milling circuits Multicompartment ball mills can be EnergyEfficient Technologies in Cement Grinding

塔东方解石矿投产时间

--磨石灰石灰机

--PCL沥青焦石油焦磨粉机

--腻子粉专用设备

--页岩和板岩

--湖南南方水泥助磨剂研发

--辊压造粒机

--山西临汾市白云石磨粉设备厂商

--磨粉研磨机磨粉研磨机磨粉研磨机

--石灰石雷蒙磨机价格

--矿石磨粉机粉碎稀土矿多少钱、

--大型液压矿石磨粉机

--料理机能将阿胶磨成粉吗

--粉碎钢筋混凝土多少钱一方

--石灰石岩石灰石制粉流程

--粉碎设备中企动力提供技术支持粉碎设备中企动力提供技术支持粉碎设备中企动力提供技术支持

--源头厂家煤炭原煤磨粉机

--石灰石粉碎机矿石磨粉机诚赢机械

--陶粒高细立磨

--等离子矿石磨粉机

--xsd2610矿石立磨作用

--矿山矿石制粉环评

--氟石加工方案

--萍乡市安源雷蒙磨配件

--方解石矿制粉加工报告

--时产300500吨页岩碎石灰石粉碎机

--电厂粉煤灰的密度

--200目雷蒙磨机器设备

--矿井通风设备选型设计图纸下载

--十公分石材钻孔机

--