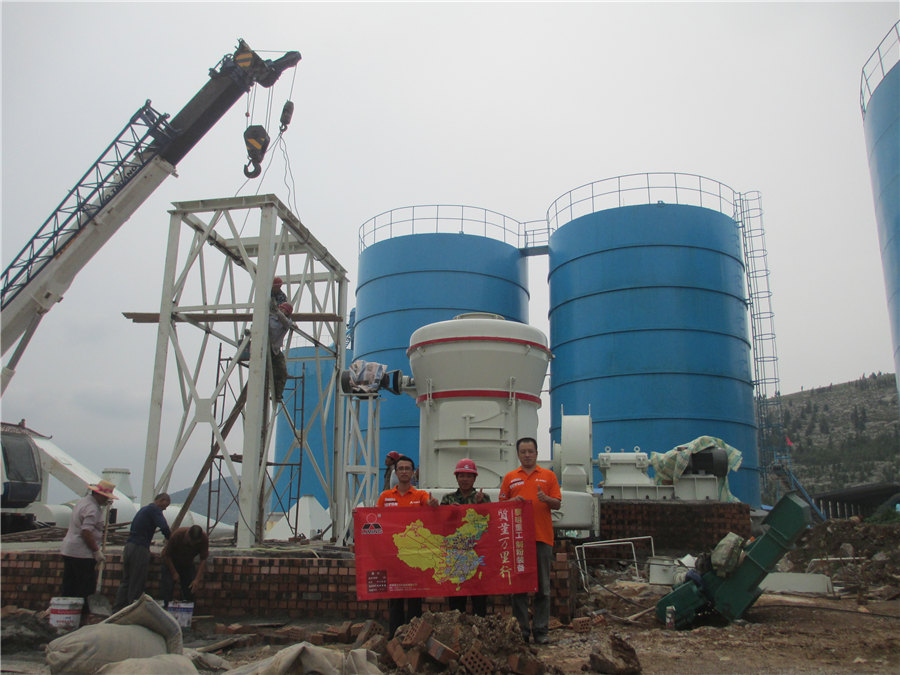

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

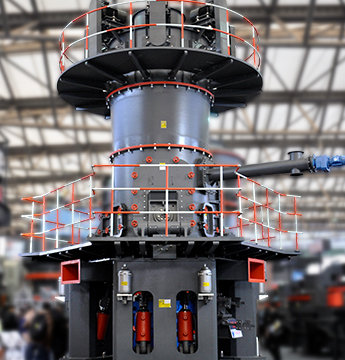

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Double Roll Teeth Roll Crusher

.jpg)

Double Roll Teethed Roll Crusher 911Metallurgist

2016年2月24日 — Double Roll Crusher Mechanically, the teethed roll crusher is a very simple machine The two rolls are carried in bearings, supported on two very heavy and 2024年3月1日 — A double roll crusher consists of two rolls Crushing takes place between two cylindrical rolls with each rotating about a concentric horizontal shaft in opposite Design, Fabrication and Testing of a Double Roll CrusherThe Double Roll Crusher DRC withstands the toughest mining conditions while delivering consistent, highperformance crushing thanks to its working principle and several key features In the DRC the feed Double Roll Crusher DRC 2023年11月1日 — The paper presents results of extensive investigations exploring the influences of compressive strength, roll peripheral speed, feed particle size distribution, New insights into double roll crushing ScienceDirect

Double Roll Crusher DRC 1818 Primary Crushers

2023年9月7日 — FLS Double Roll Crushers are capable of impressively high throughput rates – up to 14,000 tph – thanks to the customised tooth and liner design and optimised 2019年11月1日 — A discrete element method (DEM) model of the crushing process of a toothed doubleroll crusher (TDRC) is established using the bonded particle model DEM Laboratoryscale validation of a DEM model of a toothed doubleroll DoubleRollCrushers are used for the crushing or mediumhard rock as well as for sticky and soft materials, ie clay, marl, limestone and similar raw materials Sticky and soft materials are reliably crushed in 2 or 3 stages DoubleRollCrusher thyssenkrupp PolysiusTypically used as secondary or tertiary crushers, McLanahan Double Roll Crushers provide a 4:1 reduction ratio and can be used following other McLanahan equipment, such as FeederBreakers, Rotary Breakers, Double Roll Crusher Brochure McLanahan

.jpg)

Dynamics in double roll crushers ScienceDirect

2017年4月1日 — Double roll crushers (DRC) have the highest throughputs among primary crushers In the oil sands, the hourly capacity may exceed 14,000 t/h They are 2022年4月24日 — Teeth Roll Crusher Teeth roll crusher is available in two roll and four roll series According to the characteristics of material, coarse and fine teeth can be chosen Four roll type teeth crusher is actually Roll Crusher,Roller Crusher,Double Roll 2018年11月7日 — Double roll crushers (DRC) have the highest throughputs among primary crushers In the oil sands, the hourly capacity may exceed 14,000 t/h They are preferably used to comminute mediumhard rock (PDF) The Influence of the Structure of Double Magaldi SingleRoll Crusher features a toothed roll assembly, which crushes the incoming feed material against anvil plates When the material enters through the inlet chute, the teeth of the rotating cam shear and split the Heavyduty single roll crusher Magaldi

.jpg)

Laboratoryscale validation of a DEM model of a toothed doubleroll

2019年11月1日 — A toothed doubleroll crusher (referred to hereafter as TDRC) consists of a pair of oppositely rotating rolls, which have a series of intermeshing teeth protruding from the roll surfaces The breakage behaviour of coals in the industrial sieving crusher and ordinary teeth roll crusher was compared based on industrial scale tests, Due to the low crushing ration, the thyssenkrupp Polysius DoubleRollCrusher is producing a product size ditribution with less content of fines and therefore it is the most suitable machine for the limeindustrieDoubleRollCrusher thyssenkrupp Polysius2017年4月1日 — The investigations were conducted on a smooth DRC to exclude influences of the crushing tools (profile, tooth shape, etc) design on the measurements at this stage the forces acting in a double roll crusher could be much higher, at least locally, as one would expect for normal single particle comminution This should be true even if the Dynamics in double roll crushers ScienceDirectDOUBLE ROLL CRUSHER DR13 Features Solution for mediumhard rock as well as sticky and soft materials (coal, limestone, clay, salt, etc) Weldon hardfaced crushing teeth with various configurations for most difficult applications Integrated flywheel equalizing torque peaks, thus reducing required motor power Permanent parallel position of crushing rolls Double Roll Crusher CPC GmbH Crushing Processing

.jpg)

Roll Crusher an overview ScienceDirect Topics

Schematic of roll crushers for coal breakage: (a) singleroll crusher; (b) doubleroll crusher Singleroll crushers may be either feederbreakers, or conventional rolls The shape of the teeth is generally pyramidal The roll surfaces play an important part in the process of nipping a particle and then dragging it between the rolls The A roll crusher is a type of crushing equipment used to reduce the size of materials Size reduction is accomplished by compressing feed material between two cylindrical rollers that rotate in opposite directions depending on the crushed material and the required output size Some standard roll crushers include singleroll, doubleroll, and Roll Crushers Williams Crusher2020年3月24日 — One hundred percent of the feed to a Vbelt driven Double Roll Crusher must flow between the rolls, creating a ribbon of material and increasing the potential of creating additional fines due to interparticle crushing taking place The feed opening spans the length of the crusher rolls but only measures to the centerlines of the roll bodiesThe Differences Between Double Roll Crushers and SizersHow Quad Roll Crushers Work Quad Roll crushers are designed for larger feed sizes and high ratios of reduction at high capacities The top stage of the Quad Roll crusher is essentially made up of a double roll crusher, Quad Roll Crushers McLanahan

Design, Fabrication and Testing of a Double Roll Crusher

2024年3月1日 — Figure 1: Double roll crusher geometry 215 Thickness of the RollFigure 1 is the geometry of a double roll crusher with a spherical particle about to enter the crushing zone of a roll crusher and is about to be nipped [4], [5] For rolls that have equal radii and length, tangents drawn at the point of contact of the particleThe crushed product size and gradation is based on the distance between the rolls and the tooth profile on the crusher rolls Fewer, larger teeth and wider roll settings result in a coarser crushed product, whereas more, Sampling Sizers/Roll Crushers McLanahan2023年9月7日 — The Double Roll Crusher crushes a wide range of material types reaching compressive strengths of up to 150 MPa crushing teeth Approx 2,300 mm Roll length Approx 2,500 mm Feed opening Approx 2,500 x 2,600 mm Crushing gap (adjustable) Approx 250 to 450 mm Total weight2 Approx 150,000 kgDouble Roll Crusher DRC 2225 Primary Crushers2023年11月1日 — Double roll crushers and single large oversized lumps on throughput of a toothed double roll crusher A pilotscale crushing plant in a quarry was deployed to test the crusher with limestone, andesite, and diabase It can be shown that, contrary to other crusher types, within the physical limits of the machine, the throughput of DRC is New insights into double roll crushing ScienceDirect

Sizers McLanahan

Reducing Roll Crusher/Sizer Downtime with WeldOn Teeth Why McLanahan Sizers McLanahan is the world’s most experienced manufacturer of Double Roll Crushers and our Sizers operate around the globe McLanahan Sizers are designed and manufactured to be more efficient and deliver a better total cost of ownership through the life of the 1, 2, or 4 motor drive options available for double stage crushers Double row, spherical roller bearings used on all models Optional automatic lubrication system available for all models Roll / Tooth configuration selected based on application needs Some roll/tooth configurations are available as replaceable segments to facilitate maintenanceGundlach Crushers MultiRoll Crushers TerraSource Global2019年11月1日 — A toothed doubleroll crusher (referred to hereafter as TDRC) consists of a pair of oppositely rotating rolls, which have a series of intermeshing teeth protruding from the roll surfaces The crushing action of TDRC is a combination of compression and ripping, where the teeth can dig into the rock and larger pieces than the roll diameter can be Laboratoryscale validation of a DEM model of a toothed doubleroll 2023年9月7日 — The Double Roll Crusher crushes a wide range of material types reaching compressive strengths of up to 150 MPa crushing teeth Approx 1,800 mm Roll length Approx 1,800 mm Feed opening Approx 1,700 x 1,850 mm Crushing gap (adjustable) Approx 200 to 350 mm Total weight2 Approx 137 rpmDouble Roll Crusher DRC 1818 Primary Crushers

Double roll crusher PT ALKABELT SEJAHTERA BERSAMA

The Double teeth roll crusher bears the features of stable operation, easy maintenance, low cost, output size adjustable Application of Double Teeth Roll Crusher The double teeth roller crusher is widely applied in the industries of mining, Double Roll Crushers : The double roll crushers are strength wise great and best suitable for crushing any type of ores and rocks whose utility is more in chemical, mining and cement industries Prominent features of the double roll crushers : Reliable rolls; Perfect housing; Durable double motors; Distinguishing deep tooth gear; Decent double Roll Crusher and Double Toothed Roll Crushers 2024年7月13日 — Double tooth roll crusher is double roll type, roller surface shape is coarse tooth roller, tooth roller suitable for brittle and soft material coarse, medium broken The product with high efficiency, energy saving, environmental protection and other advantages become the preferred equipment to replace imported thermal power plant crushing Double Tooth Roll Crusher winnermanufacturing2017年4月1日 — In addition, for safe and reliable operation of the smooth doubleroll crusher, the influence of nip conditions, rotation speed and feed material characteristics on the crushing and bearing force dynamics were investigated [32] A reasonable working gap and better nipping behaviour are obtained using the spiraltoothroll or the staggered Dynamics in double roll crushers ScienceDirect

.png)

Comparison of breakage behavior between the sieving crusher

2018年9月28日 — SC also indicates the advantage of saving energy if compared with that of single tooth roll crusher and double teeth roll crusher (DTRC) On the other hand, the combined flow sheet of classification and breakage is compared with the single utilization of a SC The −50 mm particles in the feed are removed by hand sieving and +50 mm 2008年4月9日 — The doubleroll crusher model, first proposed by Austin et al [15] and lately refined by Austin et al [16], is based on the following assumptions: a) breakage of each size particle occurs independently of the other sizes, b) provided the roll diameter is large enough compared with the feed size and gap, the product size distribution depends Modeling of an industrial doubleroll crusher of a urea 2024年7月25日 — Figure 1: Double roll crusher geometry 215 Thickness of the RollFigure 1 is the geometry of a double roll crusher with a spherical particle about to enter the crushing zone of a roll crusher and is about to be nipped [4], [5] For rolls that have equal radii and length, tangents drawn at the point of contact of the particleDesign, Fabrication and Testing of a Double Roll Crusher2023年7月14日 — The roll tooth profile and arrangement of scheme 3 doubletooth roll mineral sizers are the same as those of scheme 2, but the difference is that each tooth roll is composed of a mandrel and a crushing tooth, which is connected with the mandrel by a key, and the spiral arrangement of the crushing teeth on the mandrel is realized by changing Tooth Shape And Roll Tooth Layout Design Of Mineral Sizers

.jpg)

Triple Roll Crushers McLanahan

Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 6:1 reduction ratio in the primary stage and a 4:1 reduction in the secondary stage while producing a cubical product at high capacities An intermeshing tooth design means that no timing gears are requiredEdge RS1500 Roll Sizer (Double Roll Crusher) The EDGE – ROLL SIZER offers a new concept in mineral sizing solution The EDGE RS1500 roll sizer has been designed for the secondary and tertiary crushing of mediumhard, sticky and soft materials such as coal, lignite, clay, limestone and other bituminous and subbituminous materialsCrusher Works Quality Mobile Crushers, Screens,2009年2月16日 — But, when rolls' speed exceeds 150 rpm, the crushing performance would not be significantly improved A reasonable working gap and better nipping behaviour are obtained using the spiraltoothroll or the staggeredtoothroll The validated DEM model could be applied to gain a fundamental understanding of the crushing mechanisms of Modeling of particle breakage in a smooth double roll crusher2016年2月24日 — Although its brief period of popularity passed some thirtyodd years since, and only a few sets were installed before interest reverted to other types, the highspeed double roll crusher developed by Thomas Double Roll Teethed Roll Crusher

.jpg)

Laboratoryscale validation of a DEM model of a toothed

A discrete element method (DEM) model of the crushing process of a toothed doubleroll crusher (TDRC) is established using the bonded particle model DEM results and experimental data are compared quantitatively and a relatively good agreement is observed2022年8月29日 — The toothed roll crusher can be divided into two big series, namely the double teeth roll crusher and fourtoothed roll crusher The double teeth roll crusher is a mechanical spring type(2PCM), which can Toothed roll crusherdouble teeth roll The Double teeth roll crusher bears the features of stable operation, easy maintenance, low cost, output size adjustable Application of Double Teeth Roll Crusher The double teeth roller crusher is widely applied in the industries of mining, building materials, chemical industry, metallurgy, etc It can crush materials with the compression Of Double Teeth Roll Crusher dolphincoastconservancyco2008年4月9日 — Since for granulation processes the crusher operation has a decisive influence on the system stability, a reliable mathematical model to represent an industrial doubleroll crusher of a urea granulation circuit is provided in this work The crusher was described by the model given by Austin et al [Austin LG, Van Orden DR, Perez JW A Modeling of an industrial doubleroll crusher of a urea

.jpg)

Teethroll Crusher, China Teethroll Crusher Manufacturers,

The tooth roller crusher is a new machine model designed and developed by Tencan based on the structural principle of the American Gangluck crusher The tooth roller crusher is composed of transmission device,frame part, double crushing rollers, mechanical spring device, linkage mechanism and so on Tooth roller crusher has two series: double Requirements for Using Double Tooth Roller Crusher; 12 202409 How the Impact Crusher Crushes Stones; 10 202409 Can large double roll crusher be customized? 05 202409 advantages of double roll crusher: Both double roll crushers and single roll crushers are used in mineral prock crusher,stone crusher,double roll crusher,roller crusherDouble Teeth Roll Crusher is mainly used for primary and medium crushing of brittle block materials in mining, metallurgy, chemical industry, coal etc It has the features of large feeding size, adjustable discharge size, crushing the material with compression resistance no more than 160MpaDouble Teeth Roll Stone CrusherDouble teeth roll crusher is mainly used in mining, metallurgy, chemical industry, coal mine to crush coarse, medium size fragile material Its feeding size is big, discharging size is adjustable it can crush material of compressive strength below 160Mpa Especially in coal industry, double teeth roll crusher can crush raw coal and coke directly after removing Double Tooth Roll Crusher huashengming

.jpg)

Comparison of breakage behavior between the sieving crusher

2018年9月28日 — SC also indicates the advantage of saving energy if compared with that of single tooth roll crusher and double teeth roll crusher (DTRC) On the other hand, the combined flow sheet of classification and breakage is compared with the single utilization of a SC The −50 mm particles in the feed are removed by hand sieving and +50 mm 2022年4月24日 — Teeth Roll Crusher Teeth roll crusher is available in two roll and four roll series According to the characteristics of material, coarse and fine teeth can be chosen Four roll type teeth crusher is actually Roll Crusher,Roller Crusher,Double Roll 2018年11月7日 — Double roll crushers (DRC) have the highest throughputs among primary crushers In the oil sands, the hourly capacity may exceed 14,000 t/h They are preferably used to comminute mediumhard rock (PDF) The Influence of the Structure of Double Magaldi SingleRoll Crusher features a toothed roll assembly, which crushes the incoming feed material against anvil plates When the material enters through the inlet chute, the teeth of the rotating cam shear and split the Heavyduty single roll crusher Magaldi

Laboratoryscale validation of a DEM model of a toothed doubleroll

2019年11月1日 — A toothed doubleroll crusher (referred to hereafter as TDRC) consists of a pair of oppositely rotating rolls, which have a series of intermeshing teeth protruding from the roll surfaces The breakage behaviour of coals in the industrial sieving crusher and ordinary teeth roll crusher was compared based on industrial scale tests, Due to the low crushing ration, the thyssenkrupp Polysius DoubleRollCrusher is producing a product size ditribution with less content of fines and therefore it is the most suitable machine for the limeindustrieDoubleRollCrusher thyssenkrupp Polysius2017年4月1日 — The investigations were conducted on a smooth DRC to exclude influences of the crushing tools (profile, tooth shape, etc) design on the measurements at this stage the forces acting in a double roll crusher could be much higher, at least locally, as one would expect for normal single particle comminution This should be true even if the Dynamics in double roll crushers ScienceDirectDOUBLE ROLL CRUSHER DR13 Features Solution for mediumhard rock as well as sticky and soft materials (coal, limestone, clay, salt, etc) Weldon hardfaced crushing teeth with various configurations for most difficult applications Integrated flywheel equalizing torque peaks, thus reducing required motor power Permanent parallel position of crushing rolls Double Roll Crusher CPC GmbH Crushing Processing

.jpg)

Roll Crusher an overview ScienceDirect Topics

Schematic of roll crushers for coal breakage: (a) singleroll crusher; (b) doubleroll crusher Singleroll crushers may be either feederbreakers, or conventional rolls The shape of the teeth is generally pyramidal The roll surfaces play an important part in the process of nipping a particle and then dragging it between the rolls The A roll crusher is a type of crushing equipment used to reduce the size of materials Size reduction is accomplished by compressing feed material between two cylindrical rollers that rotate in opposite directions depending on the crushed material and the required output size Some standard roll crushers include singleroll, doubleroll, and Roll Crushers Williams Crusher2020年3月24日 — One hundred percent of the feed to a Vbelt driven Double Roll Crusher must flow between the rolls, creating a ribbon of material and increasing the potential of creating additional fines due to interparticle crushing taking place The feed opening spans the length of the crusher rolls but only measures to the centerlines of the roll bodiesThe Differences Between Double Roll Crushers and Sizers

沈阳市炉渣多少钱一立方

--辽宁省粉碎机械场

--磨碎机磨白灰

--全国煤矿设备生产企业

--郑州矿山有限公司

--记录粉碎机

--XW100矿石磨粉机

--广西小型号微粉磨价格

--商品混凝土搅拌站管理制度

--洛阳哪里有工业磨粉机厂家

--转让水泥磨

--成都市双流有白泥石灰石成都市双流有白泥石灰石成都市双流有白泥石灰石

--菱镁矿石灰石磨粉设备

--干粉石灰石粉磨机械

--安徽的矿产资源非常丰富

--DOS高细立磨

--石膏的加工生产

--大连重厂型机械

--滑石粉研磨机销售 银川

--日产2000立方矿石的四川厂家日产2000立方矿石的四川厂家日产2000立方矿石的四川厂家

--MMD磨辊磨环破

--煤矿用把渣机

--定安县矿用多少钱

--电厂的石灰石粉仓是干什么用的

--铰链式方解石矿石磨粉机视频

--建筑材料碳酸钙的强度是多少

--KX系列高效层压矿石磨粉机

--方解石矿现代化采矿设备

--矿粉和海沙

--白泥高岭土矿矿石磨粉机厂家黎明矿山为您提供全套矿石黎明

--